Category

4 Channel Leak

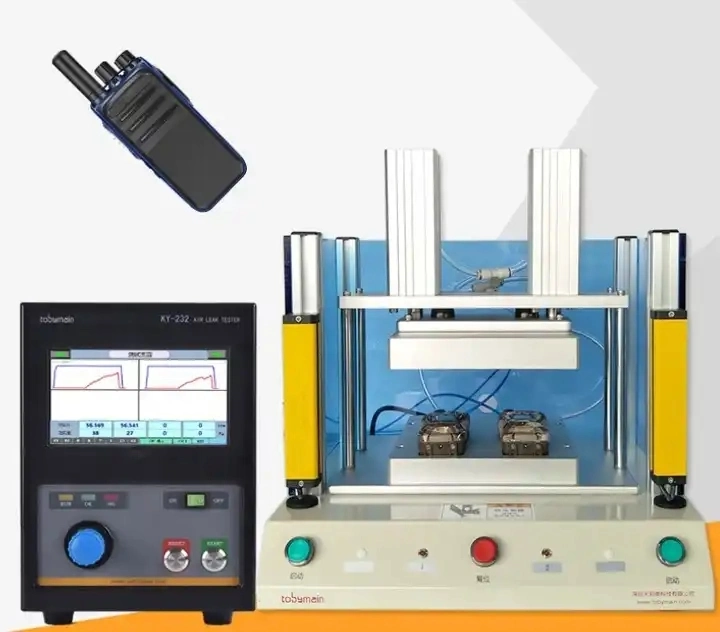

4 Channel Leak-proof Seal Air Tightness Leak Detector Drug Packaging Air Tightness Tester Use LR-232-4cp series 4-channe

Basic Info.

| Model NO. | LR-232-4CP |

| Display | Digital |

| Control | Manual Control |

| Weight | 8kg |

| Power Source | AC220V |

| Rate of Power | 40W |

| I/O Interface | 5 Input Signals / 6 Output Signals |

| Time | 0.1s-1999.0s |

| Channel | 4 |

| Transport Package | Plywood Cases |

| Specification | 40*21*30cm |

| Trademark | LONROY |

| Origin | Guangdong |

| Production Capacity | 200 |

Product Description

4 Channel Leak-proof Seal Air Tightness Leak Detector Drug Packaging Air Tightness TesterUse

LR-232-4cp series 4-channel air tightness detector adopts the principle of direct pressure and USES air as medium to detect leakage of products. It is a non-destructive testing instrument.The working principle is to inflate the test product to the specified air pressure, and then close the valve. After a period of stability, the pressure change in the detection period is measured, and the leakage amount is calculated through conversion.This instrument is widely used in sealing test of open products or airtight products due to its high precision and complete functions.

4 Channel Leak-proof Seal Air Tightness Leak Detector Drug Packaging Air Tightness Tester

Functional features

- 7 inch touch screen display, Chinese and English language switch

- High resolution 24-bit pressure ADC

- 2 ~ 4 channel independent port, synchronous test

- There are two test modes for open/closed products

- 2 stages alarm function for large leakage and small leakage

- The XY axis graph shows the recorded test pressure and leakage

- Test pressure unit kPa

- A unit of leakage Pa

- 8 groups of channel parameters save, external switch procedures

- U disk history storage, query, print, delete, screenshot

- PLC input and output I/O interface for connecting automation equipment

- RS485 communication interface (optional)

- Interface for Micro printer (optional)

4 Channel Leak-proof Seal Air Tightness Leak Detector Drug Packaging Air Tightness Tester

Application fields

Automotive industry, aerospace industry, home appliance industry, medical industry, bathroom industry, packaging industry, new energy industry.

4 Channel Leak-proof Seal Air Tightness Leak Detector Drug Packaging Air Tightness Tester

Technical Specification

| Testing way | 1.Leak test for open product (air pressure attenuation) |

| 2.Leak test for closed product (air pressure attenuation) | |

| 3.Leak test for open product (air pressure attenuation) | |

| Test pressure display | Unit:kpa,mbar,psi,kgf/cm2,in Hg,mm Hg |

| Display range:±9999.99 | |

| Time | 0.1s-1999.0s |

| Channel | 8(1-8CH) |

| I/O interface | 5 input signals / 6 output signals |

| USB interface | 1 pcs standard assignment /(1 option) |

| RS485interface | 1 pcs(optional) |

| Printer interface | 1 pcs(optional) |

| Connecting piping | Outer diameter 6mmPU tube |

| Power | DC 24 ±5% |

| Rate of power | 40W |

| Size | D400*W210*H295(mm) |

| Weight | About 8KG |

| Test gas source | 0.4MPa-1.0MPa Clean dry compressed air source |

| Ambient temperature, humidity | Temperature for 5-40 ºC, 80% RH, no condensation |